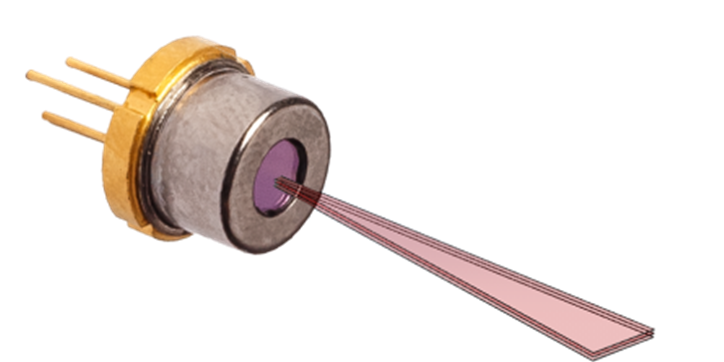

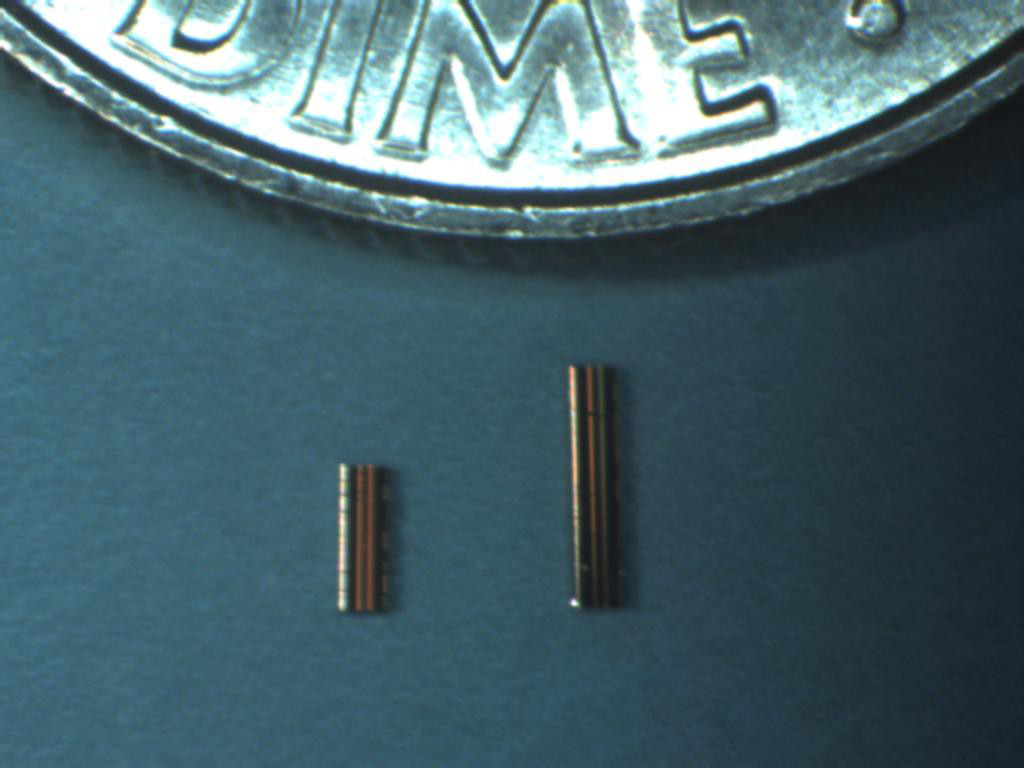

SemiNex Corporation unveils a new sales and application engineering office in Liaoyang, China to support customers with product selection, system integration, pricing and supply across the entirety of the Asian continent. SemiNex now directly supports new business in Asia for high power laser diodes spanning various industries including consumer devices, professional medical, industrial, military and telecommunications markets. Specifically, the fast-emerging LiDAR applications, including those used in autonomous vehicles, will now benefit from this direct support and the introduction of the new SemiNex Multi-Junction Laser with 300% the power of prior best-in-class lasers. The new multi-junction laser diode produces 80 watts at 1550nm with a 95um aperture width yielding more than 3X the power of current single junction laser diodes at this wavelength.

The Asia office will better support new applications and existing business in China, Korea, Japan, and across Asia. This allows SemiNex to showcase these products directly with the Asian consumer, whereas before, it was only possible to do so remotely, especially with limited travel due to COVID-19 restrictions. An increase in sales, customer satisfaction, and further expansion are already being experienced due to the opening of this new office. SemiNex recently presented its products at the CIOE trade show in Shenzen, China, which in normal years attracts over 89,000 professionals. During the show SemiNex supported dozens of applications and a myriad of customers with in-person meetings.

With the inauguration of this new workspace, SemiNex better responds to customer questions, such as product pricing, specifications, product selection assistance and supply inquires. This comes in a year of pandemic challenges, uncertainty and ever changing variables. Despite these circumstances, SemiNex continues conducting successful business throughout the Far East with increasing sales and support of its laser diodes.

The building, in which the new office is located, is a state of the art structure which recently finished construction. Its central location in Liaoyang allows for easy customer access and convenience, making it effortless to directly schedule in-person meetings, remote calls and web conferences during convenient Asia daily work times. Visitors to the new office will find it contains all the modern amenities one would expect in our present age, providing guests with a comfortable and pleasant experience during their visit. It will serve as a central hub for SemiNex China in the years to come.

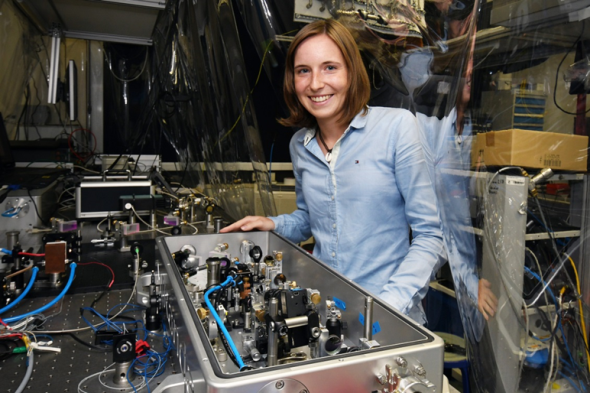

Applications Engineer Hanyu Yang is managing the new Chinese location. Her background includes a master’s degree in engineering from Northeastern University, USA and prior experience at leading medical device companies such as Becton Dickinson Medical. Ms. Yang’s cultural background, international experience and extensive language skills provide our Asian customers with exceptional service.

Ed McIntyre, Vice President of Sales, works closely with Ms. Yang and noted, “I’m very excited about having Hanyu in China to support our customers in real time to bridge the communications gap with direct and timely customer support. That can be very challenging when working on a new engineering project.”

The new office in the Far East has regular business hours from 9am to 5pm China Standard Time (UTC+8) and can be reached at +86 15641953339 / +86 (0419) 5850799, WeChat 15641953339 or email at hyang@seminex.com.