Compact system and assembly process for producing high volume, low cost, “eye safe” lasers

Peabody, Mass. – December 16, 2014 – SemiNex Corporation, a Peabody, Massachusetts-based manufacturer of high power infrared lasers, was awarded Patent 8,811,439 on August 19, 2014 for a compact laser system and the associated self-aligning assembly and packaging process.

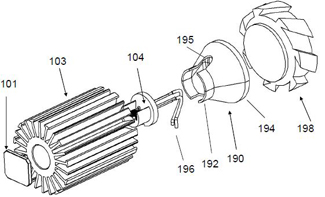

“The laser engine system we’ve designed provides an efficient means of integrating a laser and a cooling system into a very small form factor,” explained Vice President of Design & Engineering John Callahan, PhD. “It’s well suited for applications where overall system cost and space are at a premium.” The patented system consists of a semiconductor laser, cooling mechanism, and optics.

SemiNex’s laser diode technology delivers low-cost, high-power laser sub-systems. The laser engine patent adds to the company’s patents related to their chip technology and laser systems. SemiNex-patented technology is used throughout various industries; including medical, military, and aerospace.

Patent 8,811,439 covers technology that addresses the needs of the consumer market, where high volume and low cost are key factors in design. In addition to the design of the system, the patent covers the assembly and packaging processes. These are designed to be self-aligning to reduce manufacturing cost while increasing manufacturing throughput. “SemiNex took an innovative approach to reducing manufacturing time through elegant engineering,” explained Chief Executive Officer David Bean.

The technology is currently in use at SemiNex, and the company has additional patents pending.